Rongcheng water conservancy clap door series materials are divided into cast iron, stainless steel, carbon steel, composite material (FRP) and other materials, while the clapping door can be divided into many kinds, such as floating box type clapping door, flat panel clapping door, sleeve type clapping door, etc. It is a one-way valve installed at the outlet of the river drainage pipe. When the tide level of the river is higher than the outlet of th...

INQUIRYRongcheng water conservancy clap door series materials are divided into cast iron, stainless steel, carbon steel, composite material (FRP) and other materials, while the clapping door can be divided into many kinds, such as floating box type clapping door, flat panel clapping door, sleeve type clapping door, etc. It is a one-way valve installed at the outlet of the river drainage pipe. When the tide level of the river is higher than the outlet of the outlet pipe and the pressure is greater than the pressure in the pipe, the flap panel will automatically close to prevent the river tide from pouring into the drainage pipe. At present, the door is divided into suspension type, single door, double door, energy-saving type and other models.

Structure and working principle of clapping door:

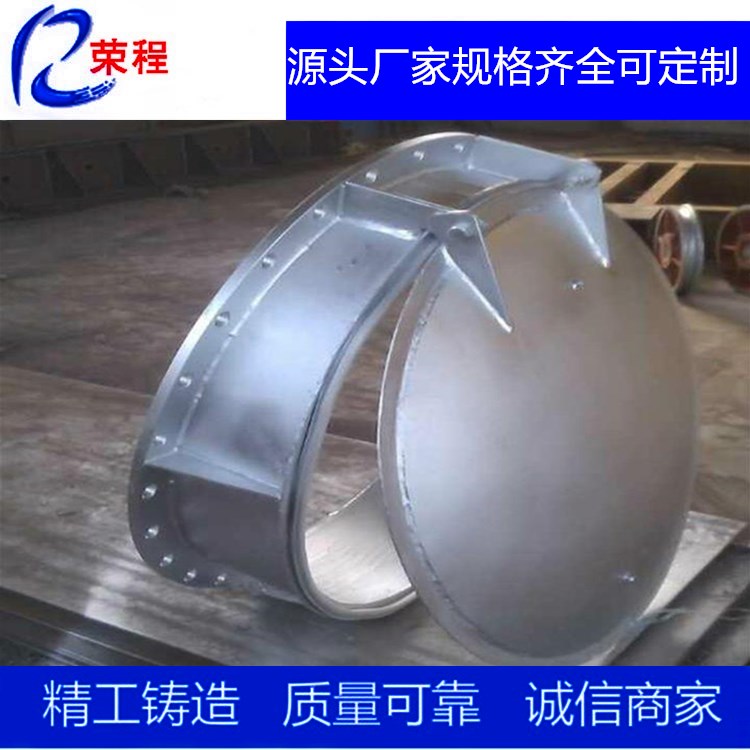

It is composed of four parts: seat, valve plate, sealing ring and hinge.

The round and square outlets for one-way flow are of strict structure and reliable operation. The opening and closing forces are from the water source pressure without manual operation. When the water pressure in the clap door is greater than the pressure outside the clapper, it will open; otherwise, it will be closed.

Door performance:

Suitable medium: water, river water, river water, sea water, life, industrial sewage

Scope of application:

It is suitable for water conservancy system, municipal sewage, flood control and drainage in cities, sewage treatment plant, water plant, etc.

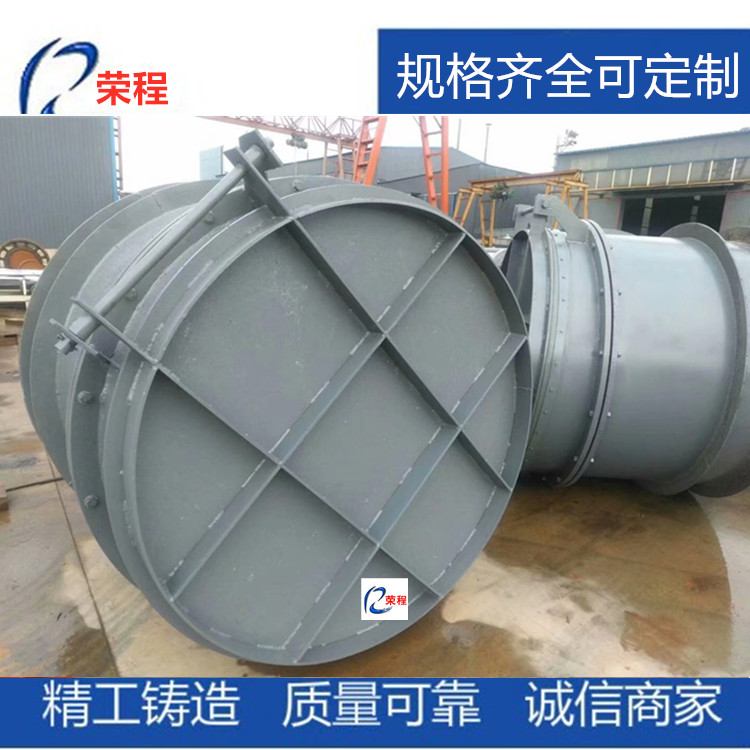

Product specifications and categories:

The specifications of the clapping door are divided into two types: Circular clapping door and square clapping door, which can be designed and produced according to the size and shape of the outlet; the clapping door can be divided into hollow floating plate flap door and plate type clapper door.

Installation of clapping door:

The installation of clapping door can be done by flange connection and concrete pouring.

The allowable deviation between the center of clapping door and the center of runner shall not be greater than 3.0 mm

There should be 400 mm installation space around the door, and the slope of 1:5 should be made under the exit of the clapping door.

Accessories for door installation: bolts or expansion wires are stainless steel or carbon steel with anticorrosive treatment; rubber or rubber gasket is used for sealing parts.

Accessories for rubber pad installation of door: bolts or expansion wires are stainless steel or carbon steel with anticorrosive treatment; rubber or rubber gasket is used for sealing parts. The installation requirements of rubber pad of cast iron flap door: flange connected cast iron clapper door is divided into flange connection of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of flange of. The rubber pad structure of cast iron clapping door consists of door racking seat, door cover and connecting shaft. The racking door seat adopts double flange structure, and the lower flange plays the role of connecting and fixing the clapping door, and the upper flange plays the role of sealing water stop and drainage. The fixed flange of rubber pad of cast iron flap door adopts national standard, and it is compatible with the steel flange sold in the market. The fixed flange of rectangular flap door is non-standard flange. The tilt angle of the racket is generally 75 degrees. For large-scale clapping door, the inclination angle can be increased, generally 80 degrees, and the purpose is to make the door cover open better.

The other flange of the door seat is a sealing water stop flange, with U-groove on its surface, Y-shaped sealant strip embedded in it. The sealing strip and FRP are coated with imported high-grade adhesive, which is firmly bonded, and has the more water resistance performance, and will not fall off due to long-term immersion and frequent opening. The sealing strip is made of imported rubber raw materials and is vulcanized in the curing bed. Its form, flexibility and sealing performance have been explored and practiced by our factory for many years. After continuous improvement, the sealing effect is very ideal. Its flexibility performance slows down the impact of the flap cover on the clapping door seat due to instantaneous water return, and protects the clap door seat and the flap door cover. Therefore, the rubber strip plays a double role of sealing and buffering. For example, when the pump is shut down, the water outlet of the clapping door suddenly lacks water and closes instantly. Because the weight of the flap cover is relatively light, under the slow down of the rubber strip, most of the external force has been eliminated invisibly, so that the flap cover is closed tightly without damage.

Caliber specification: Circular dn200-3600mm, square 200-3800mm.