Headstock gear, also known as screw headstock gear, is a kind of machinery that uses screw rod to connect with gate leaf directly or through guide slider and connecting rod, and the screw moves up and down to open and close the gate. With the extensive development of water conservancy and hydropower projects, the gate is widely used in reservoir irrigation area, river embankment, hydropower station and other engineering projects. The knowledge of in...

INQUIRYHeadstock gear, also known as screw headstock gear, is a kind of machinery that uses screw rod to connect with gate leaf directly or through guide slider and connecting rod, and the screw moves up and down to open and close the gate. With the extensive development of water conservancy and hydropower projects, the gate is widely used in reservoir irrigation area, river embankment, hydropower station and other engineering projects. The knowledge of installation, debugging and maintenance should also be popularized. For the construction and installation units and management departments, this technology and knowledge should be popularized in order to ensure the project quality and give full play to the project benefits.

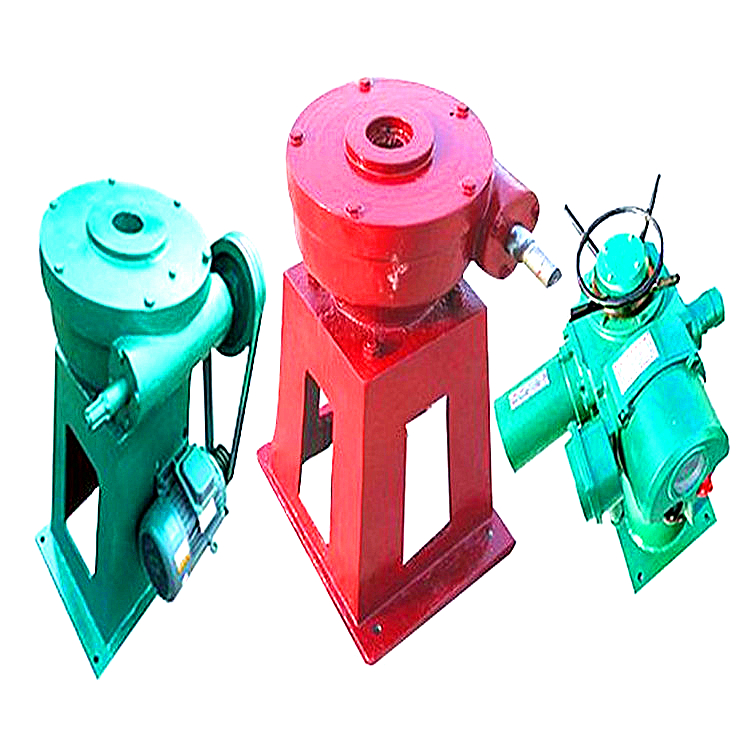

The hoist has the following characteristics in structure design and performance

1. According to the needs of users, it can be equipped with electric device and handle for manual use.

2. The design and production standard of this machine is sd298-88 technical conditions for LQ screw hoist issued by Ministry of water resources and Ministry of energy. All parts shall comply with the standards.

3. The machine adopts worm gear, variable speed, nut or screw rotation to make the gate move up and down to achieve the function of opening and closing.

4. According to the requirements of users, magnetic lock device can be set to prevent others from opening.

5. The screw length can be produced according to the user's requirements, and the distance between two lifting points can be designed according to the user's requirements.

Installation steps of hoist:

1. When installing the screw hoist, it is necessary to keep the layout plane of the base foundation 180 ° horizontal; the contact area between the base of the hoist and the layout plane of the foundation should reach more than 90%; the screw axis should be vertical to the horizontal plane measured on the gate platform; it should be stable and vertical to the ram lug hole to avoid the screw inclination, causing local stress and damaging the parts.

2. Put the manual screw hoist in the installation position. Put a limit plate on the screw, screw the screw into the machine from the lower part of the beam, and then cover the limit plate when the screw is exposed from the upper part of the machine. The lower part of the screw is connected with the gate.

3. The foundation for installing the hoist must be stable and safe. The concrete of the base and foundation components shall be poured according to the provisions of the drawings. When the concrete strength does not reach the design strength, it is not allowed to dismantle and change the temporary support of the hoist, and it is not allowed to carry out trial operation.

4. During the installation, the center shall be aligned according to the lifting center line of the gate, so that the vertical and horizontal center line deviation shall not exceed plus or minus 3mm, and the elevation deviation shall not exceed plus or minus 5mm. Then the second stage concrete is poured or connected with the embedded steel plate.

5. For the installation of electrical equipment of the product, it must comply with the provisions of the drawings and instructions, and all electrical equipment are reliably grounded.

6. After the product is installed, clean the machine, repair the damaged protective paint, and pour grease.

When selecting this product, the hoist shall declare in advance:

1. Total length of screw, thread length, center distance of lifting point (double lifting point type)

2. Lengthen the screw part and whether there are segmenting requirements.

3. Special electrical control requirements

4. Whether it is necessary to add screw protection device, if so, provide relevant drawings or location drawings.

5. Other special requirements.

6. The layout of hoist foundation is only for reference in the design of water supply building. If there are special requirements, the factory can change it, and the anchor bolts are supplied at random.

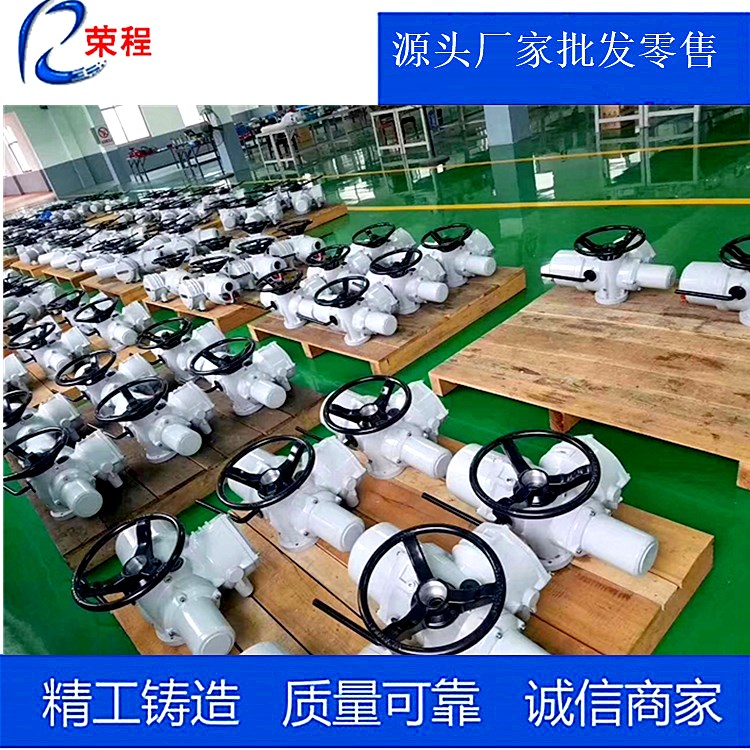

The screw series products produced by Rongcheng water conservancy include: screw hoist 3t-100t; horizontal push screw hoist with lock 0.5-3t; hand wheel hoist 0.5-3t; QLP horizontal push screw hoist 0.5-3t; QLF three prevention magnetic lock screw hoist 0.3t-30t; QLC side swing screw hoist 0.5t-2t; QL hand screw hoist; hand electric screw hoist 3t-100t (single and double crane); swing hoist; QLC side swing screw hoist 0.5t-2t; Electric hoist; qlz direct screw hoist: ql-sd double lifting point flashlight dual-purpose screw hoist 2-60t. Multi clock products to meet the needs of different customers, welcome to order.