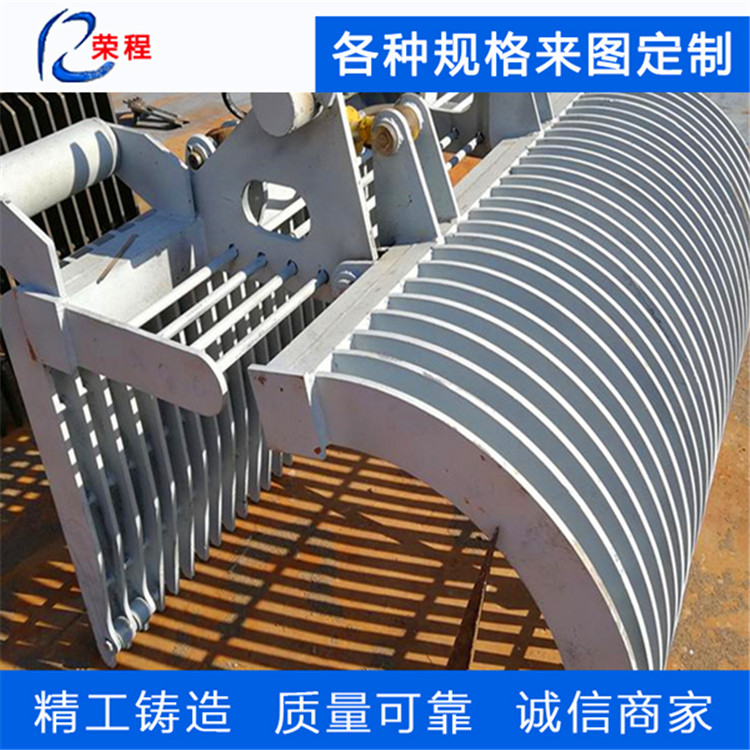

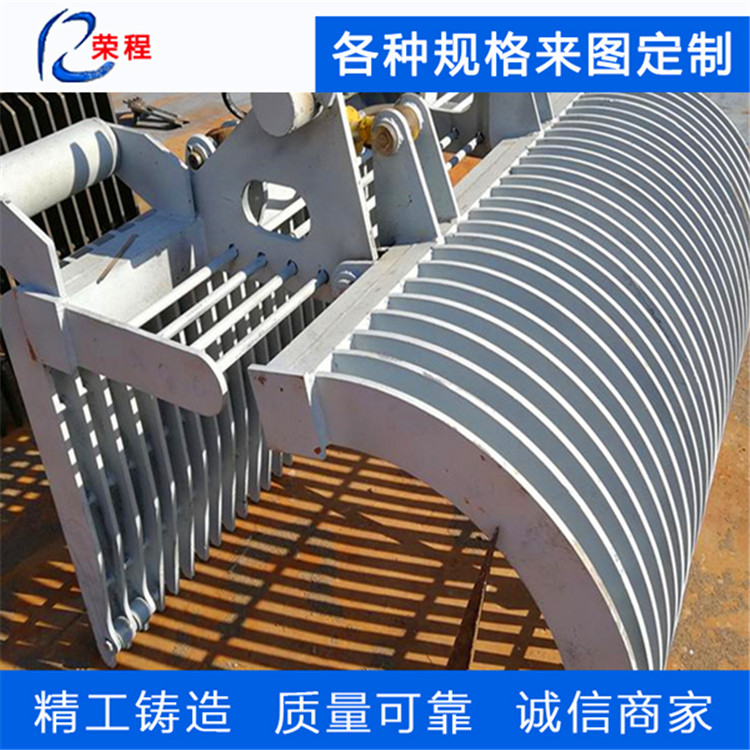

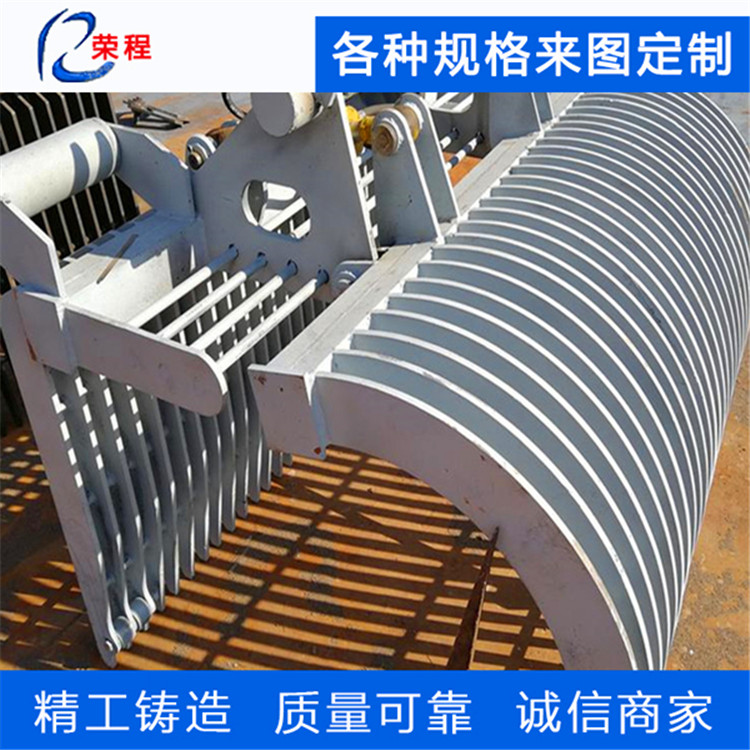

The wire rope ****action grid decontamination machine consists of frame, steel rope drive and over torque protection device, two ****action steel ropes and one open and close rake steel rope in the middle, guide wheel, rope release switch, rake bucket opening and closing device, rake bucket, grating s****ip, guide rail and slag supporting plate, slag skimming plate, slag guide plate, elec****ic con****ol equipment, etc.

INQUIRYThe wire rope traction grid decontamination machine consists of frame, steel rope drive and over torque protection device, two traction steel ropes and one open and close rake steel rope in the middle, guide wheel, rope release switch, rake bucket opening and closing device, rake bucket, grating strip, guide rail and slag supporting plate, slag skimming plate, slag guide plate, electric control equipment, etc.

The working cycle process is as follows: after the work instruction is issued, the steel rope drive device starts to release the rope, and the rake bucket goes down along the guide rail from the position (at the end of the last cycle skimming), and the skimming plate decreases with the rake bucket under the action of self weight. When the skimming plate is reset, the rake bucket is opened and continued to descend under the traction of the middle steel rope under the push of the open and close rake device (electric push rod) until it reaches the limit position under the channel (well). The trolley stops and the steel rope loosens. The rope is loosened and the rope is loosened. The rope release switch acts, starts the electric push rod and retracts, and loosens the middle steel rope, so that the rake bucket can be closed under the action of self weight. After the rake teeth are inserted into the grid clearance, the steel rope drive device drives the rope to take up the rope, further forces the rake bucket to close completely, and then the rake bucket and the bucket will move up along the guide rail, remove and transport the grid slag intercepted by the grid until it touches the skimming plate. Under the action of the relative movement of the two, the grid slag is skimmed out and the slag guide plate falls into the slag bucket (or conveyor), and a working cycle is completed. In the process of operation, if the rope drive device is over twisted due to unexpected obstacles, it will alarm and stop automatically when the torque distance reaches the set value; for example, when the rake bucket opening and closing device is overloaded and the electric push rod thrust rises to the set value, the push rod over torque switch acts to ensure the system safety.

Wire rope traction cleaner is an energy-saving and efficient mobile grid cleaning equipment, which is widely used in many water intake areas, which breaks the design of traditional models. Domestic * design concept, and adopt a number of advanced technology research and development of new generation grid cleaning equipment, this equipment unique suspension guide rail design, so that it can meet the requirements of various sites and spaces to a large extent. Because of its novel equipment and simple and reasonable structure, it is not necessary to destroy the existing structure and civil engineering. Reducing the investment in civil engineering transformation is an ideal choice to replace the existing system equipment. A fully automatic steel wire rope traction cleaner can serve multiple sets of grilles. When running, the pulley can stop at each clean-up grid accurately, and start a cleaning process. After grabbing the dirt, the grab will run directly to the discharge area (slag storage unit) along the track without secondary transportation, and then automatically remove the dirt repeatedly until all the trash is removed at all grills.

The wire rope traction grid decontamination machine can be divided into fixed type (gsgs-g type) and mobile type (gsgs-y type) according to the needs of different grid slot width. The grid cleaner is generally applicable to the water intake of urban water plant, sewage treatment plant, various pump stations, urban flood control and drainage facilities, so as to intercept large and coarse debris and garbage in the water, protect the impeller of water pump from damage, and ensure the subsequent treatment workers Normal operation of sequence. When the width of the grid slot is more than 3m and there are multiple groups arranged in parallel, blq-y mobile grid cleaner should be used to clean the lower grid with a set of combined devices for water sewage removal, so as to save investment cost and facilitate operation management and maintenance. The installation angle of GSGS type grid cleaner is generally 60 ° ~ 90 °, and the effective clearance of the grating plate can be selected within 15-100mm as required, and the groove depth of the grid is generally 4-12m.

Front rake type trash interceptor drawn by wire rope. It is suitable for water intake of urban, water plant, sewage treatment plant, various pump stations, urban flood control and drainage facilities, so as to intercept large and coarse debris and garbage in the inflow, protect the impeller of water pump from damage and ensure the normal operation of subsequent treatment process. When there are multiple sets of grids arranged in parallel, blq-y mobile grid cleaner is adopted. It uses a set of combined devices to clean the sewage of multiple underwater grilles one by one, thus saving investment cost and facilitating operation management and maintenance.

The mobile grid cleaner structure mobile grid machine includes grating piece, frame, working platform, walking mechanism, cleaning mechanism, rake mechanism, garbage trolley, 18kg/m light rail, overload protection device, steel wire rope anti loosening device, travel control and electrical control box. The power supply, drive execution structure, control system, electric control box and other driving execution structures and control systems are located on the rack, and relevant embedded parts are provided for the construction unit.

1. equipment and rake tooth specifications

The equipment specifications are divided into gsly300-3600 type according to the machine width.

Width

Over 1800mm, made and online.

The rake rack gap is divided into

The selection of various specifications, such as 1mm, 3mm, 5mm, 10mm, 20mm, 30mm, 40mm and 50mm, is selected by the water quantity, lifting height, total amount of solid-liquid separation, shape and particle size of the separated substances, and different materials are selected at the same time.

2. equipment length and specification

The standard trench depth of equipment is 1535mm, which can be lengthened arbitrarily according to the user's needs and actual use conditions. Special specifications are designed separately. The great advantages of the cleaning machine produced by Hebei Shunyu Environmental Protection Technology Co., Ltd. are high automation, high separation efficiency, small power consumption, no noise and good corrosion resistance. Under the condition of unattended, continuous and stable work can be guaranteed. Overload safety protection installation is set. In case of equipment failure, it will automatically stop the machine, which can avoid overload work of the equipment. The cleaning machine can adjust the operation interval of the equipment according to the user's needs to realize periodic operation; it can automatically control the liquid level difference before and after the grid; and it has the manual control function to facilitate maintenance. Users can choose according to different work needs.

Rongcheng water conservancy steel wire rope traction grid decontamination machine, grid cleaner, rotary cleaner material is mainly carbon steel, stainless steel 304 and 201, 316 according to customer needs casting materials, details sun manager for technical communication guidance.

Note to purchase: the equipment can adjust the operation interval according to the user's needs to realize periodic operation; it can automatically control the liquid level difference before and after the grid; and it has manual control function to facilitate maintenance. Users can choose according to different work needs. Because the structure of the equipment is reasonable, it has strong self-cleaning ability when the equipment works, and it will not jam, so the daily workload is very small. Welcome to call 13582492022 wechat same number, and sun manager for technical communication and guidance.